Miscellaneous

A lot of stuff I've built won't fit under any other category than this. Mostly, it's useful little testing

instruments, but also my own prototype breadboards.

My first High-Voltage Power Supply

This lethal thing should make any electricity safety

inspector gasp for his breath. It is just a simple 300 VDC power supply I built for development work with electron

tubes. It's a simple design. A rectifier salvaged from a TV set (the red one with fins) is mounted on a black acrylic

plate, together with a coil from a fluorescent tube assembly and two electrolytic capacitors from the same TV set

(the upright standing metal cans). A fuse is mounted in one corner. It's 220 VAC straight in. The device has no

feet, and had to be put on something insulating, or I would get very nasty sparks from the underside. Terrible.

But if you just keep your hands off, there is no danger. I can't remember ever getting any shocks from any of my

designs.

This lethal thing should make any electricity safety

inspector gasp for his breath. It is just a simple 300 VDC power supply I built for development work with electron

tubes. It's a simple design. A rectifier salvaged from a TV set (the red one with fins) is mounted on a black acrylic

plate, together with a coil from a fluorescent tube assembly and two electrolytic capacitors from the same TV set

(the upright standing metal cans). A fuse is mounted in one corner. It's 220 VAC straight in. The device has no

feet, and had to be put on something insulating, or I would get very nasty sparks from the underside. Terrible.

But if you just keep your hands off, there is no danger. I can't remember ever getting any shocks from any of my

designs.

Conductivity Tester

In all electric design work you sometimes need to know

if you have a connection or not. Of course you can drag the AVO-meter around everywhere, but this little conduction

tester, consisting solely of one Sonalert (beeper) and a battery is much tougher and doesn't have to be in view

all the time. If it beeps you have a connection. The device turned out to be invaluable in car repair.

In all electric design work you sometimes need to know

if you have a connection or not. Of course you can drag the AVO-meter around everywhere, but this little conduction

tester, consisting solely of one Sonalert (beeper) and a battery is much tougher and doesn't have to be in view

all the time. If it beeps you have a connection. The device turned out to be invaluable in car repair.

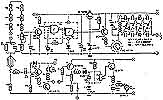

Stat-O-Meter: Static Electricity Meter

I was dealing with

static electricity at work, or rather, tried to get rid of it. The problem was knowing how much static electricity

we were dealing with, and where it was generated. I needed some sort of measuring instrument. Meters could be bought,

but they were expensive and difficult to use (over-qualified). I built one myself, instead. The design was very

simple: the input of a FET OP-amp needing only a few nanoamperes is connected more or less straight to the antenna,

and so the amplifier is measuring the leak currents flowing in the air.

I was dealing with

static electricity at work, or rather, tried to get rid of it. The problem was knowing how much static electricity

we were dealing with, and where it was generated. I needed some sort of measuring instrument. Meters could be bought,

but they were expensive and difficult to use (over-qualified). I built one myself, instead. The design was very

simple: the input of a FET OP-amp needing only a few nanoamperes is connected more or less straight to the antenna,

and so the amplifier is measuring the leak currents flowing in the air.

Using my Stat-O-Meter it was easy to trace static electricity, to check if a carpet created static charges,

and the like. Furthermore it could measure electrical changes in the atmosphere, measuring the weak currents flowing

through the air towards the clouds. These currents change when a thunderstorm is approaching. The meter has a recorder

output, making it possible to connect an X-t strip chart recorder and make long time measurements.

Infrared Photography

At work we were doing reading and detection of counterfeit bills by reading their image with a very special

camera and comparing with the properties of real bills. The problem was that banknotes sometimes were so dirty,

worn and torn that the camera had problems catching the picture properly. I found this so interesting that I started

to study infrared technology to see if it was possible to use other wavelengths than the visible. Kodak has a terrific

textbook on the subject, and armed with this I got myself a few filters, filter holders, film, lights and other

equipment, and started photographing dollar bills.

Sure enough, using short wave IR, with Kodak Wratten filter no. 87,

the dirt disappeared and the picture came through nice and clear. This picture is shot with f16. The bills to the

right are real (with real degradation) and the ones to the left are xerographic copies from different copy machine

manufacturers. I had to modify my camera. A camera lens does not refract IR in the same way as it does visible

light, so I had to calculate a new distance scale and draw it on the focusing ring. Of course I couldn't see through

the viewfinder, as infrared filters are completely opaque (black) in visible light.

Sure enough, using short wave IR, with Kodak Wratten filter no. 87,

the dirt disappeared and the picture came through nice and clear. This picture is shot with f16. The bills to the

right are real (with real degradation) and the ones to the left are xerographic copies from different copy machine

manufacturers. I had to modify my camera. A camera lens does not refract IR in the same way as it does visible

light, so I had to calculate a new distance scale and draw it on the focusing ring. Of course I couldn't see through

the viewfinder, as infrared filters are completely opaque (black) in visible light.

And what's this? Sailboat racing in the middle of the

winter? A negative image? No, it happens to be in June. It is the sail race “All-around Lidingö” (north of

Stockholm) photographed in infrared light. This is evident from the strongly reflecting trees in the background,

and the nearly black water. The boats' sails also reflect strongly. The gas tank in the background is painted to

“eat” all incoming IR.

And what's this? Sailboat racing in the middle of the

winter? A negative image? No, it happens to be in June. It is the sail race “All-around Lidingö” (north of

Stockholm) photographed in infrared light. This is evident from the strongly reflecting trees in the background,

and the nearly black water. The boats' sails also reflect strongly. The gas tank in the background is painted to

“eat” all incoming IR.

IR Telescope

I was involved

in the House Owner's Society and their work to make house-owning more economical. One big problem is heat leakage

from houses, mostly to find it and to measure how much heat is disappearing. I had seen the heat cameras from AGA

(a Swedish pioneering company in the IR camera business) and also seen the price tag. Just renting one was so expensive

you didn't do it unless there were severe suspicions about some fault. I decided to try to build a heat seeking

telescope, with telescopic sight and temperature indication in the form of a tone, so that you could sweep over

the wall of a house and listen to the leaks. A fantastic design that was unfortunately never finished.

I was involved

in the House Owner's Society and their work to make house-owning more economical. One big problem is heat leakage

from houses, mostly to find it and to measure how much heat is disappearing. I had seen the heat cameras from AGA

(a Swedish pioneering company in the IR camera business) and also seen the price tag. Just renting one was so expensive

you didn't do it unless there were severe suspicions about some fault. I decided to try to build a heat seeking

telescope, with telescopic sight and temperature indication in the form of a tone, so that you could sweep over

the wall of a house and listen to the leaks. A fantastic design that was unfortunately never finished.

The telescope consists of an aluminium tube with a

parabolic IR mirror in one end (which I actually managed to get from the camera department at AGA. Just think of

the things you can get hold of, if you talk to the right people) and a small secondary mirror at 45 degrees angle

in the middle of the telescope, directing the picture towards a sensor sitting in focus, right outside the telescope

tube. The picture shows what it looks like when looking straight into the telescope. You do see the camera?

The telescope consists of an aluminium tube with a

parabolic IR mirror in one end (which I actually managed to get from the camera department at AGA. Just think of

the things you can get hold of, if you talk to the right people) and a small secondary mirror at 45 degrees angle

in the middle of the telescope, directing the picture towards a sensor sitting in focus, right outside the telescope

tube. The picture shows what it looks like when looking straight into the telescope. You do see the camera?

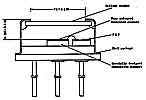

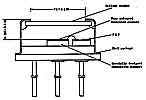

The sensor was

a derivating kind, having a silicon window. The semiconductor inside needed to “see” a reference temperature and

the true object temperature switched at about 10 Hz. I solved that by putting a rotating shutter, a “chopper” in

front of the sensor. The output from the sensor looked like a square wave, having an amplitude equal to the difference

in temperature between the chopper and the object. Hopefully, the chopper would keep a stable temperature throughout

the measurement period...

The sensor was

a derivating kind, having a silicon window. The semiconductor inside needed to “see” a reference temperature and

the true object temperature switched at about 10 Hz. I solved that by putting a rotating shutter, a “chopper” in

front of the sensor. The output from the sensor looked like a square wave, having an amplitude equal to the difference

in temperature between the chopper and the object. Hopefully, the chopper would keep a stable temperature throughout

the measurement period...

I got as far as mounting everything, and I managed to detect a soldering iron in the telescope's field of view.

Of course, the operator was not supposed to look through the telescope. It was only for the infrared radiation.

Instead I put a telescopic sight on the outside, one that I bought very cheap from a mail-order company. For the

operator's comfort under prolonged use, I mounted everything on a rifle butt, one that I got extremely cheap at

a gunshop. It looked like some futuristic raygun.

Geiger Counter

The year was 1986. Suddenly some underpaid nuclear power plant workers

had finished playing in Chernobyl (actually meaning “black existence,” a fitting name) in Ukraine, and in one second

they had changed everybody's lives. The people at the Forsmark nuclear power plant in Sweden raised the alarm,

and suddenly having your own radiation counter was very popular. Buying one was unthinkable, as it cost several

thousands of kronor. I found some schematics and built one, but ran almost immediately into problems getting the

sensor, the Geiger-Müller tube. It turned out that everyone else had thought just like me, and there were

no GM tubes available in the whole country. After a lot of nagging I managed to get one from ELFA (a large mail-order

electronics dealer) and I could finish the counter. The GM tube is inside the yellow tube to the right. It was

such a disappointment! The counter worked, but there was nothing (enough) radioactive in my neighbourhood. Nothing

at all.

The year was 1986. Suddenly some underpaid nuclear power plant workers

had finished playing in Chernobyl (actually meaning “black existence,” a fitting name) in Ukraine, and in one second

they had changed everybody's lives. The people at the Forsmark nuclear power plant in Sweden raised the alarm,

and suddenly having your own radiation counter was very popular. Buying one was unthinkable, as it cost several

thousands of kronor. I found some schematics and built one, but ran almost immediately into problems getting the

sensor, the Geiger-Müller tube. It turned out that everyone else had thought just like me, and there were

no GM tubes available in the whole country. After a lot of nagging I managed to get one from ELFA (a large mail-order

electronics dealer) and I could finish the counter. The GM tube is inside the yellow tube to the right. It was

such a disappointment! The counter worked, but there was nothing (enough) radioactive in my neighbourhood. Nothing

at all.

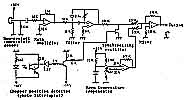

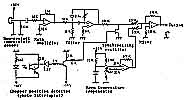

The circuit board

is in the middle of the box. The blue electrolytic capacitors at the bottom are part of the voltage doubler, giving

800-900 volts to the GM tube. The tube itself is lying down to the right, with its hat off. The round, black thing

is the thin detector window. This window is so thin, both beta and alpha particles can penetrate it and ionise

the gas inside the tube. Gamma radiation, on the other hand, is detected by the electrons it knocks out of the

nickel walls of the tube, which in their turn builds an ionised bridge in the detector gas, and so trigger the

tube. The most prominent parts of the schematic is the voltage multiplier to the right and the voltage divider

for the detector to the left. Below this, is the GM tube.

The circuit board

is in the middle of the box. The blue electrolytic capacitors at the bottom are part of the voltage doubler, giving

800-900 volts to the GM tube. The tube itself is lying down to the right, with its hat off. The round, black thing

is the thin detector window. This window is so thin, both beta and alpha particles can penetrate it and ionise

the gas inside the tube. Gamma radiation, on the other hand, is detected by the electrons it knocks out of the

nickel walls of the tube, which in their turn builds an ionised bridge in the detector gas, and so trigger the

tube. The most prominent parts of the schematic is the voltage multiplier to the right and the voltage divider

for the detector to the left. Below this, is the GM tube.

I got some uranium nitrate (UO2 (NO3)2+6H2O) from a friend and was finally able to verify that

the counter worked, that the intensity of the radiation decreased with the square of the distance, that paper would

attenuate this and that much, but that was all. Later, I realised that the levels of radiation in nature were much

lower, and needed instruments of a more advanced kind.

Prototyping Breadboards

Building electronic prototypes, especially in the high-frequency domain, can be really problematic if you haven't

got some good prototype board to build on. Wire-wrapping doesn't work very well for audio and high frequencies,

and universal breadboards with a 2.54" hole matrix and straight copper strips on the underside (à la

Veroboard) are difficult to solder (and re-solder) and are not very useful for high frequencies, as they lack a

ground plane. It's difficult mounting shielding, too.

I manufactured my own universal breadboard,

which solved the problem. It had a building matrix for IC's with 2.54" spacing on the top side, plus areas

for analogue circuitry and lines for low impedance power feed. The underside was completely covered with tinned

copper laminate, making for safe and good shielding and low impedance earthing. You can't have much lower impedance

to ground than just drilling a hole straight through the board and soldering the component to the ground plane.

I manufactured my own universal breadboard,

which solved the problem. It had a building matrix for IC's with 2.54" spacing on the top side, plus areas

for analogue circuitry and lines for low impedance power feed. The underside was completely covered with tinned

copper laminate, making for safe and good shielding and low impedance earthing. You can't have much lower impedance

to ground than just drilling a hole straight through the board and soldering the component to the ground plane.

Constructions on this type of board had characteristics close to those attainable with customized, factory made

circuit boards.

This lethal thing should make any electricity safety

inspector gasp for his breath. It is just a simple 300 VDC power supply I built for development work with electron

tubes. It's a simple design. A rectifier salvaged from a TV set (the red one with fins) is mounted on a black acrylic

plate, together with a coil from a fluorescent tube assembly and two electrolytic capacitors from the same TV set

(the upright standing metal cans). A fuse is mounted in one corner. It's 220 VAC straight in. The device has no

feet, and had to be put on something insulating, or I would get very nasty sparks from the underside. Terrible.

But if you just keep your hands off, there is no danger. I can't remember ever getting any shocks from any of my

designs.

This lethal thing should make any electricity safety

inspector gasp for his breath. It is just a simple 300 VDC power supply I built for development work with electron

tubes. It's a simple design. A rectifier salvaged from a TV set (the red one with fins) is mounted on a black acrylic

plate, together with a coil from a fluorescent tube assembly and two electrolytic capacitors from the same TV set

(the upright standing metal cans). A fuse is mounted in one corner. It's 220 VAC straight in. The device has no

feet, and had to be put on something insulating, or I would get very nasty sparks from the underside. Terrible.

But if you just keep your hands off, there is no danger. I can't remember ever getting any shocks from any of my

designs.